PUMP INSTALLATION AND APPLICATIONS

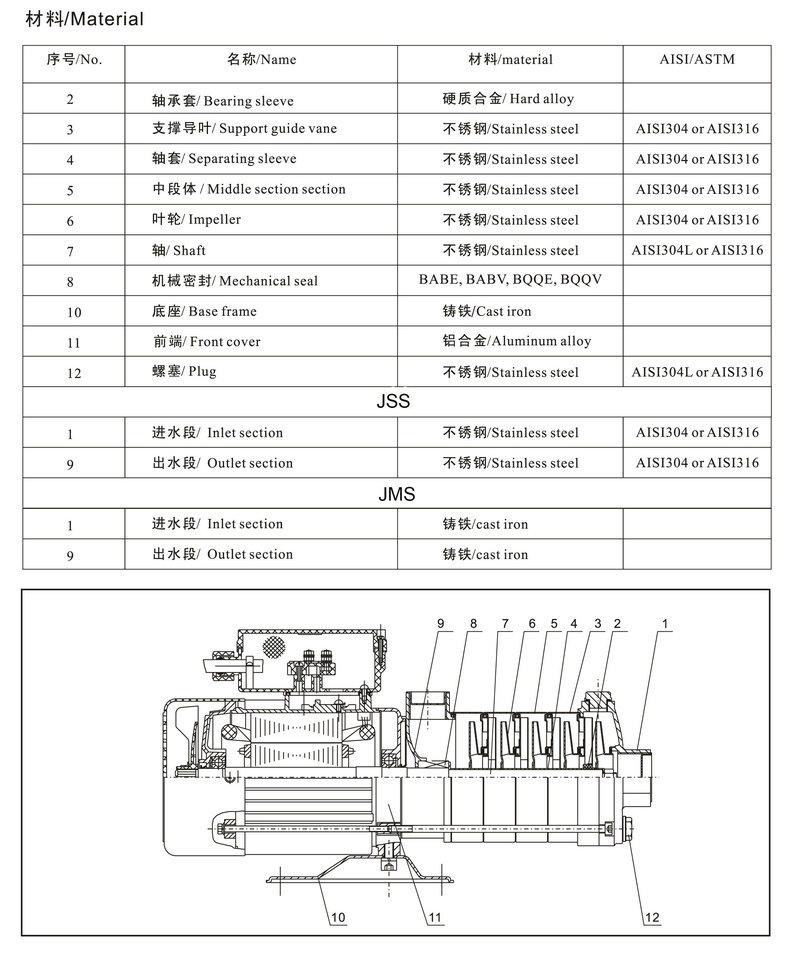

JMS series is segmental multistage stainless steel pump; The material of inlet and

outlet is cast iron; the liquid part is made of SUS304,. Under processing of advanced

welding equipment, heat treatment, the stress caused by end-cut plate in tension and

press forming is eliminated to make in high strength, no deformation, long life, safe

and reliable usage; Applied mechanical seal type ensure watertight in long-time continuous

operation. The material of frame is aluminum; it is under low-noise and less-vibration and

durability. Insulation class F, protection IPX55, continuous duty; Single-phase with thermal

protector from T1 to ensure safety and convenience.

1. Air-conditioning system

2. Water treatment

3. Pressure boosting for the water on processing line.

4. Heating and cooling water on industrial processing line

5. Water supply and pressure boosting (drinking water, weak chlorine water)

6. Fire-fighting system

7. Convey thin, clean, non-flammable and non-explosive liquid without solid granules and fibers

Model | POWER | Qn(m3/h) | | SIZE | RATE |

P2(KW) | |||||

JMSL1-20(T) | 0.25 | 1 | 13.5 | G1/G1 | 2900 |

JMSL1-30(T) | 0.25 | 21 | |||

JMSL1-40(T) | 0.25 | 27 | |||

JMSL1-50(T) | 0.37 | 33 | |||

JMSL1-60(T) | 0.37 | 37 | |||

JMSL2-20(T) | 0.25 | 2 | 16 | G1/G1 | 2900 |

JMSL2-30(T) | 0.37 | 24 | |||

JMSL2-40(T) | 0.55 | 2 | 32 | G1/G1 | 2900 |

JMSL2-50(T) | 0.55 | 40 | |||

JMS2-20(T) | 0.37 | 2 | 14 | G1/G1 | 2900 |

JMS2-30(T) | 0.37 | 21 | |||

JMS2-40(T) | 0.55 | 28 | |||

JMS2-50(T) | 0.55 | 35 | |||

JMS2-60(T) | 0.75 | 42 | |||

JMS4-20(T) | 0.55 | 4 | 15 | G1/4/G1 | 2900 |

JMS4-30(T) | 0.75 | 22 | |||

JMS4-40(T) | 0.75 | 30 | |||

JMS4-50(T) | 1.0 | 38 | |||

JMS4-60(T) | 1.1 | 45 | |||

JMS8-10(T) | 0.55 | 8 | 12 | G11/2/ G11/2 | 2900 |

JMS8-15(T) | 0.75 | 20 | |||

JMS8-20(T) | 1.0 | 24 | |||

JMS8-25(T) | 1.5 | 27 | |||

JMS8-30(T) | 1.85 | 36 | |||

JMS8-35(T) | 2.2 | 43 | |||

JMS8-40(T) | 2.2 | 48 | |||

JMS8-10B(T) | 0.55 | 8 | 9 | G11/2/ G11/2 | 2900 |

JMS8-20B(T) | 0.75 | 19 | |||

JMS8-30B(T) | 1.1 | 26 | |||

JMS8-40B(T) | 1.5 | 37 | |||

JMS8-50B(T) | 2.2 | 46.5 | |||

JMS8-60BT | 3.0 | 52 | |||

JMS12-10(T) | 1.0 | 12 | 13.5 | G11/2/ G11/2 | 2900 |

JMS12-15(T) | 1.5 | 20 | |||

JMS12-20(T) | 1.85 | 12 | 28 | G11/2/ G11/2 | 2900 |

JMS12-25(T) | 2.2 | 33.5 | |||

JMS12-30T | 3.0 | 39 | |||

JMS12-10B(T) | 0.75 | 12 | 9.5 | G11/2/ G11/2 | 2900 |

JMS12-20B(T) | 1.1 | 19.5 | |||

JMS12-30B(T) | 1.85 | 29.5 | |||

JMS12-40B(T) | 2.2 | 39.5 | |||

JMS12-50BT | 3.0 | 50 | |||

JMS16-10(T) | 1.0 | 16 | 10 | G2/G2 | 2900 |

JMS16-20(T) | 1.5 | 20 | |||

JMS16-30T | 2.2 | 16 | 30 | G2/G2 | 2900 |

JMS16-40T | 3.0 | 40 | |||

JMS20-10(T) | 1.0 | 20 | 10.5 | G2/G2 | 2900 |

JMS20-20(T) | 1.85 | 20 | |||

JMS20-30T | 3.0 | 31.5 | |||

JMS20-40T | 4.0 | 40 | |||

220-240V/50HZ,110V/60HZ, models are available on request | |||||

1. Liquid temperature: +5℃ ~ +60℃

2. Max ambience temperature: +50℃

3. Max pressure: 10 bar

4. Max suction head: No self-priming

5. Maximum inlet pressure is limited by the maximum operating pressure

1. Request for the flow and pressure

2. The mechanical seal configurations is selective as ordinary type and pure water type and heat water type etc.

3. Applied region’s voltage and frequency: single-phase: 220-240V/50Hz;220V-240V/60Hz;110-120V/60Hz is available; three-phase:

380-415V/50Hz;380-415V/60Hz is available.

4. Applied region’s request for safety certific4. Confirm the bore of outlet and inlet.

5. Plug’s type and length (no plug, Chinese plug. Europe plug, UL plug … is available)

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved