Features:

Description | |

Model No: H600-1 | |

Material: PP | Deodorize type: Regular |

Idle speed:2850r/min | Input flow: 100L/min |

Input Voltage: AC230V/50Hz | Power: 600W |

Current: 2.2A | Power factor:0.65 |

Control: Automatic / manual | Equipment operation :interval |

Shaft of Pump: Horizontal | Type of the pump: Centrifugal pump |

Impeller type: Vane | Blade: 3 blade |

Height of maximum evacuation: ≤7m | Horizontal of maximum evacuation: ≤70m |

Start liquid level:90mm | Stop liquid level:40mm |

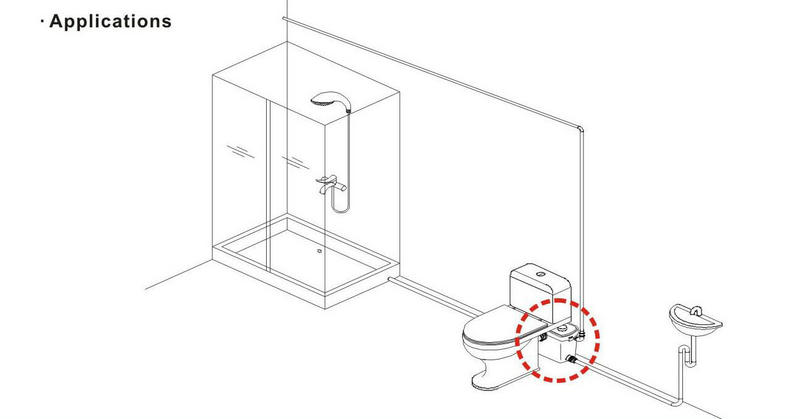

Sewage Inlet: D100MM 1PC | Sewage temperature: 1—90(℃) |

D40MM 2 PCS | 33.8—194(℉) |

Sewage Outlet: D40mm 1pc | Capactiance: 10uF/450V(CBB60) |

Degree of protection: IPX4 | Switch: 1 pc |

Motor Hot Proection Level:125℃ | |

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved