Pump's Application

The JDP- H is High lift pump

Submersible pump JDP-H is specifically engineered to handle the tough demanding tasks of removing excess water from swimming pools, swimming pool covers spas, fountains, basements or any other area with excess accumulated water.

The pump has been manufactured to the highest standards of workmanship and materials to give users many years of exceptional performance. The pump housing, constructed of durable polymer material, provides protective shield for the motor.

| Type | Power (w ) | Max.Flow ( L/H) | Max.Head (m) | Max.Depth (m) | Max.Grain (mm) | Outlet | Length of Cable (m) |

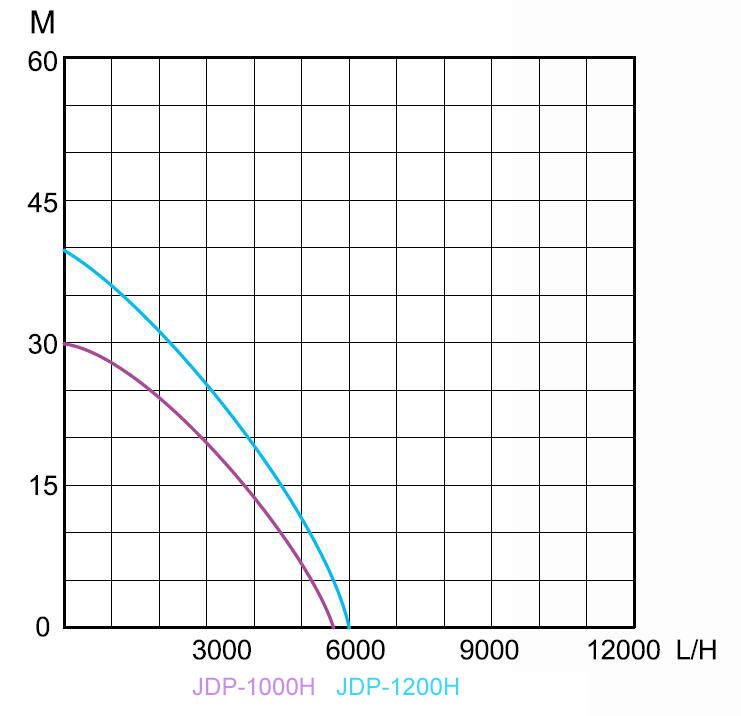

| JDP-1000H | 1000 | 5500 | 30 | 12 | 5 | 1" | 10 |

| JDP-1200H | 1200 | 6000 | 40 | 12 | 5 | 1" | 10 |

| 220-240V/50HZ,110V/60HZ, models are available on request | |||||||

Liquid temperature up to 35℃

Max. ambient temperature: 40℃

Protection IP X8

Max. grain size: 5mm

Pools/Garden ponds/Basements/Pool covers/Home floods/Garages/Spas/Etc

Pump body: Plastic

Impeller: Plastic

Motor Closed, externally ventilated

Insulation class: B

Protection class: IPX8

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved