APPLICATIONS

.Wastewater drainage in factories,construction sites and commercial facilities

.Drainage system in municipal sewage treatment plants

.Drainage station in residential quarters

.Municipal projects

.Methane pools and field irrigation in countryside

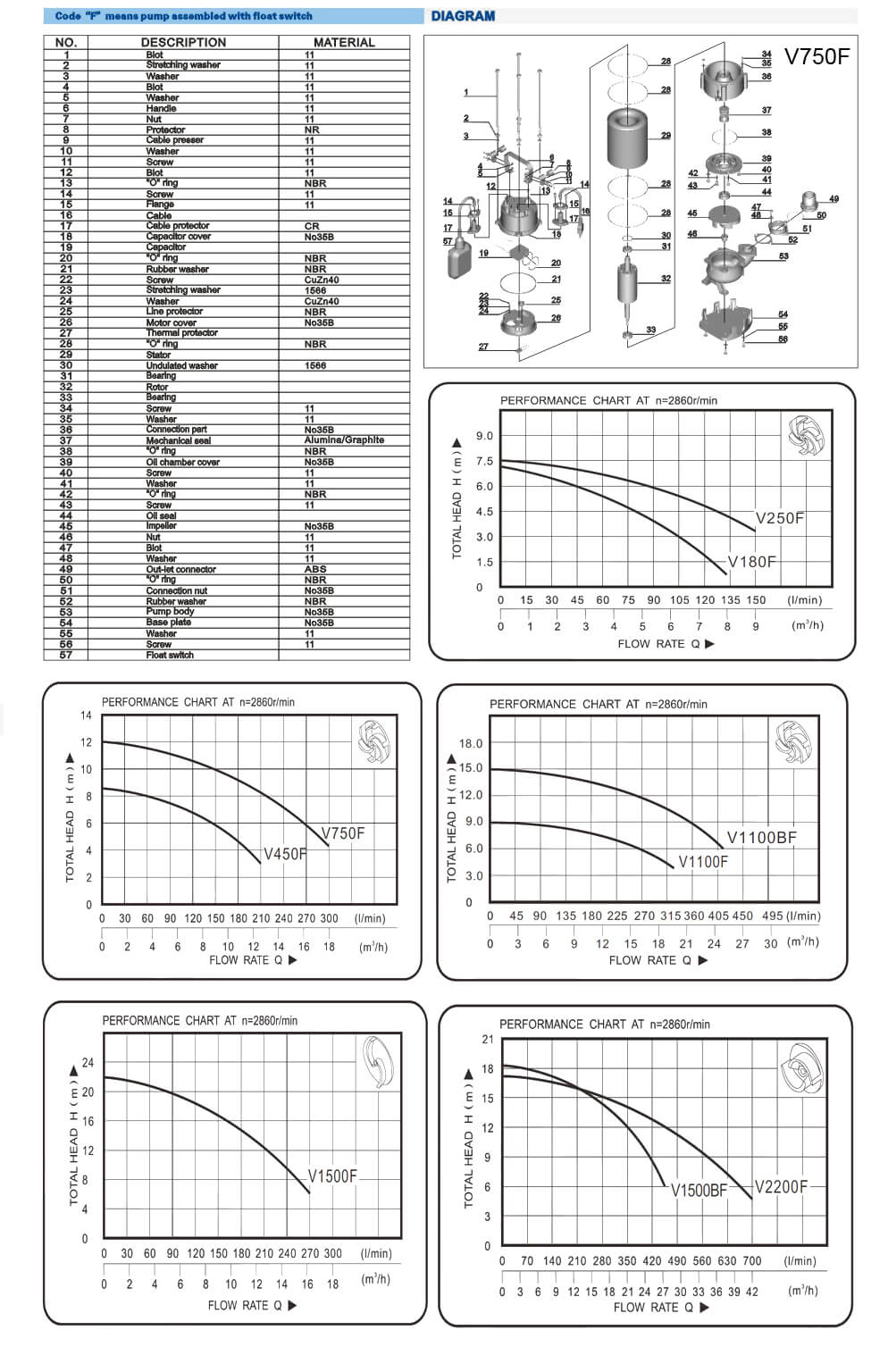

| Type | Power | Outlet Diameter (mm) | Max.Flow | Max.Head | Cable Length | GW | NW | Packaging Dimension |

| (Kw) | (L/min) | (m) | (m) | (kg) | (kg) | (cm) | ||

| V180F | 0.18 | 40;32;25 | 144 | 7 | 5.3 | 9 | 8 | 19*19*39 |

| V250F | 0.25 | 40;32;25 | 175 | 7.5 | 5.3 | 9.5 | 8.5 | 19*19*40 |

| V450F | 0.45 | 50 | 320 | 9 | 6 | 17.5 | 16.5 | 26*20*52 |

| V750F | 0.75 | 50 | 340 | 10.5 | 6 | 22 | 21 | 26*20*56 |

| V1100F | 1.1 | 50 | 400 | 9 | 6.0 | 23.5 | 22.5 | 29*23*58 |

| V1100BF | 1.1 | 50 | 416 | 15 | 6.0 | 22 | 21 | 29*23*55 |

| V1500F | 1.5 | 50 | 300 | 22 | 10 | 27 | 26 | 60*36*26 |

| V1500BF | 1.5 | 50 | 450 | 18.5 | 10 | 28 | 27 | 60*36*26 |

| V2200F | 2.2 | 75 | 700 | 17 | 10 | 33 | 32 | 60*36*26 |

| V2200BF | 2.2 | 100 | 990 | 18.5 | 6.0 | 38 | 37 | 60*36*27 |

| 220-240V/50HZ,110V/60HZ, models are available on request | ||||||||

PUMP

◪ Max.immersion depth:5m

◪ Max.liquid temperature:+40℃

◪ Liquid pH value: 4-10

◪ Liquid kinematic ciscosity: 7x10(-7)~23x10(-6)m2/s

◪ Max.liquid density: 1.2x10(-3)kg/m3

MOTOR

◪ Copper winding

◪ Built-in thermal protector

◪ Stainless steel welded shaft

◪ Indulation class: F

◪ Protection class: IPX8

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved