Features:

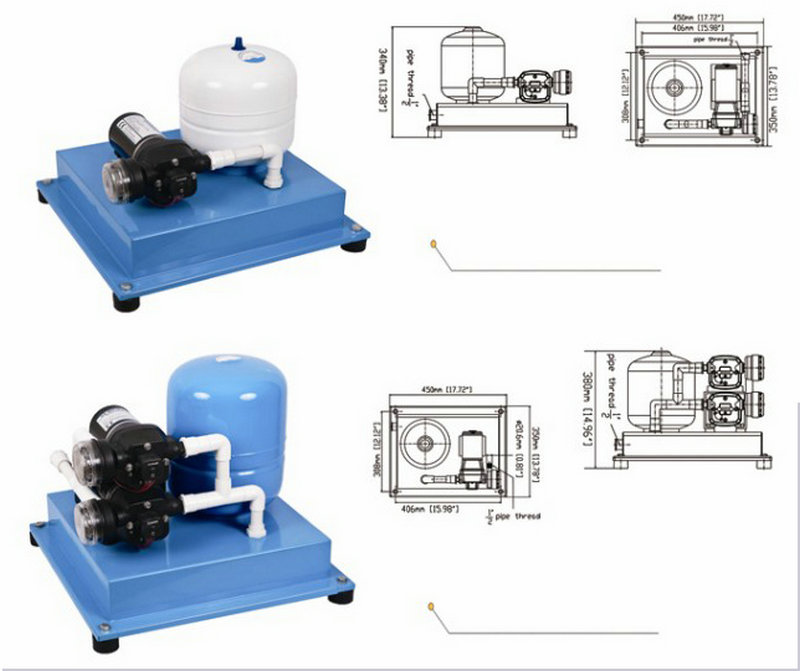

.Integrated pump and accumulator tank system

.Compact design installs easily in convenient locations

.Available in 12, 24, 115 and 230 Volts models to service the RV, Bus Conversion and Commercial Coach markers etc...

. Can run dry without harm

.FDA materials in pump and accumulator tank for drinking water

.Self-priming up to 6ft. (2m)

.Includes assorted ports for easy installation

.Install a water strainer to protect pump from debris.

Model | Voltage(V) | Electric Current (A) |

Flow (Liters/Min) |

pressure (PSI) | Packing | Carton Size(cm) | G.W.(KG) | N.W. (KG) |

| GSFL-35 | 12V | 6A | 12.5 | 35PSI | 1pc/ctn | 46*46*30 | 12 | 11 |

| GSFL-35X | 24V | 2.5A | 25 | 35PSI | 1pc/ctn | 46*46*30 | 12 | 11 |

| GSFL-40/44 | 12V | 6A | 17 | 40PSI | 1pc/ctn | 46*46*35 | 14.5 | 13.5 |

| GSFL-40X/44X | 24V | 2.5A | 34 | 40PSI | 1pc/ctn | 46*46*35 | 14.5 | 13.5 |

.Marine

.Yacht

.Recreation vehicle

.Caravan

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved