APPLICATIONS

.Small electrical irrigation and drainage equipments

.Particularly applied in urban well water pumping,field irrigation and drainage,garden irrigation and household water supply,as well as drainage of industrial accumulated water,water supply and drainage for construction livestock breeding,etc

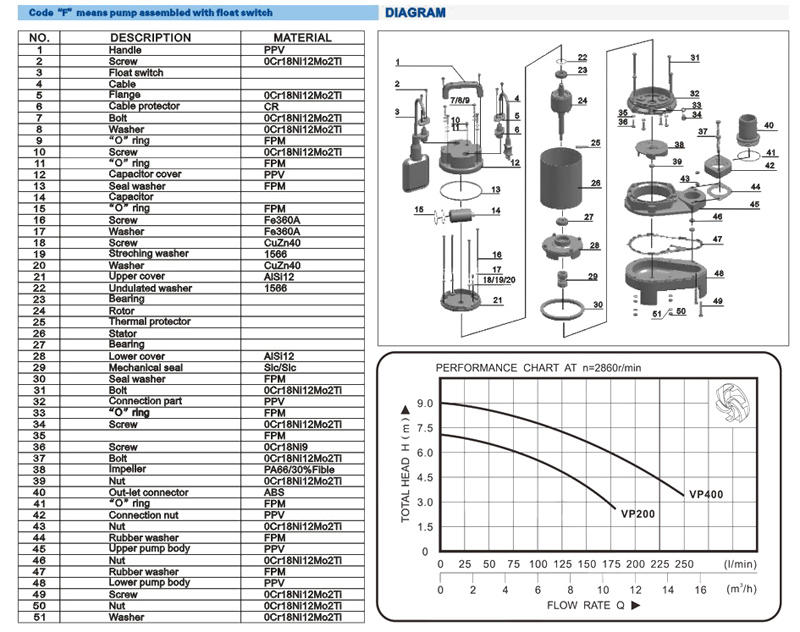

Type | Power | Outlet Diameter (mm) | Max.Flow | Max.Head | Cable Length | GW | NW | Packaging Dimension |

(Kw) | (L/min) | (m) | (m) | (kg) | (kg) | (cm) | ||

VP200 | 0.2 | 50 | 180 | 7 | 6.0 | 7.8 | 6.5 | 40*27*20 |

VP400 | 0.4 | 50 | 250 | 9 | 6.0 | 9.0 | 8.0 | 42*27*20 |

220-240V/50HZ,110V/60HZ, models are available on request | ||||||||

PUMP

◪ Max.immersion depth:5m

◪ Max.liquid temperature:+40℃

◪ Liquid pH value: 6.5-8

MOTOR

◪ Copper winding

◪ Built-in thermal protector

◪ Stainless steel welded shaft

◪ Indulation class: F

◪ Protection class: IPX8

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved