APPLICATIONS

Heavy-Duty Blige Pumps integrate the highest quality bearings, brushes, alloys and magnets designed to withstand extreme usage cycles. Pump all employs an exclusive shaft and motor compartment, reducing wear and significantly extending pump life. Advanced resin compositions incorporated in exterior to resist chemicals such as engine oil, aggressive detergents and hose plasticizers. Attwood's Heavy Duty bilge has unsurpassed durability and efficiency in a compact design to ensure electrical energy is converted to the pump rather than excess heat.

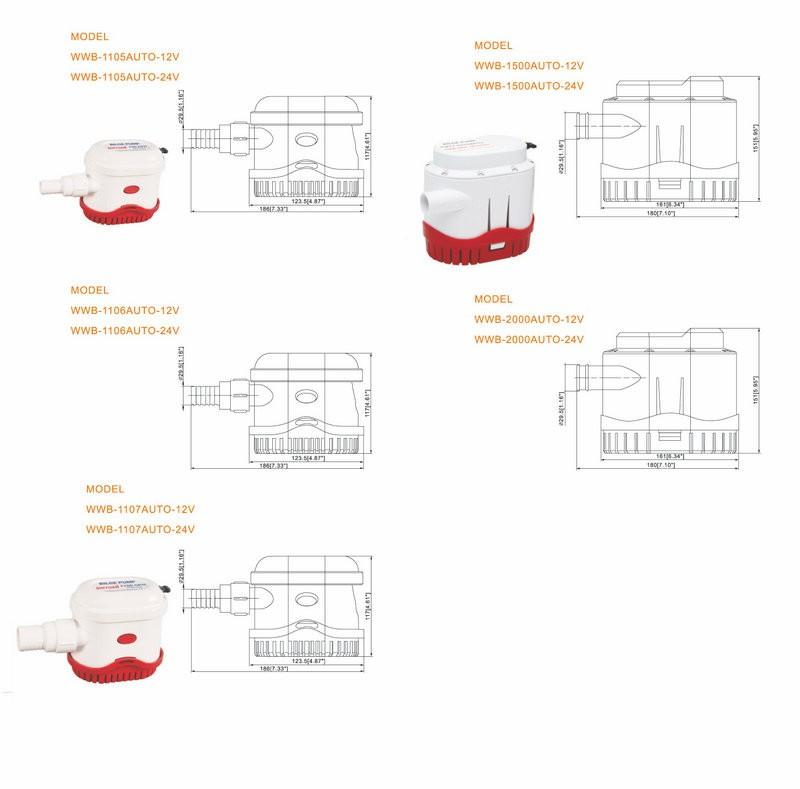

MODEL | DESCRIPTION | QTY/ctn | SIZE OF CARTON cm | G.W./ctn kgs |

| WWB-1105Auto | 500GPH | 30 | 58X30X40 | 15 |

| WWB-1106Auto | 700GPH | 30 | 58X30X40 | 15 |

| WWB-1107Auto | 1100GPH | 30 | 58X30X40 | 15 |

| WWB-1500Auto | 1500GPH | 10 | 62X41X18 | 19 |

| WWB-2000Auto | 2000GPH | 10 | 62X41X18 | 19 |

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved