PUMP INSTALLATION AND APPLICATIONS

Product Features:/ Safer pump body / Energy Saving / Simple structure /

Easy to operate / With thermal protector / High efficiency , low noise .

Product Applications:/ Floor water booster / Hot water circulation system

of floor heating or boiler / Water circulation system of solar energy or heat pump .

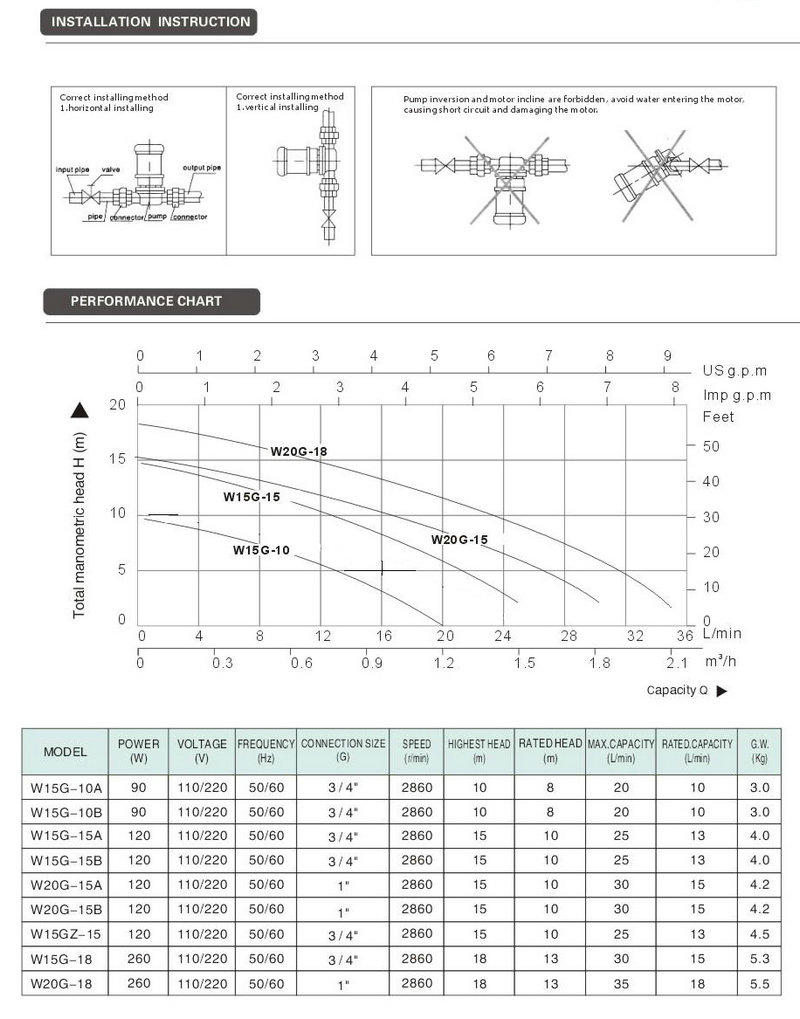

Model | Power | Q.MA | H.MAX | Inlet/Outlet | G.W. Kg |

| W | L/min | m | |||

| W15G-10A | 90 | 20 | 10 | 3/4” | 3 |

| W15G-10B | 90 | 20 | 10 | 3/4” | 3 |

| W15G-15A | 120 | 25 | 15 | 3/4” | 4 |

| W15G-15B | 120 | 25 | 15 | 3/4” | 4 |

| W20G-15A | 120 | 30 | 15 | 1” | 4.2 |

| W20G-15B | 120 | 30 | 15 | 1” | 4.2 |

| W15GZ-15 | 120 | 25 | 15 | 3/4” | 4.5 |

| W15G-18 | 260 | 30 | 18 | 3/4” | 5.3 |

| W20G-18 | 260 | 35 | 18 | 1” | 5.5 |

| 220-240V/50HZ,110V/60HZ, models are available on request | |||||

. pump body: Cast iron/Brass/ Stainless steel

. impeller: Engineering plastic

. Shaft: Ceramic/ Stainless steel

. Bearing base: Stainless steel

. Bearing: Ceramic/ Baptist antimony graphite

. Shield cover: Stainless steel

Max system pressure ≤1.0MPa

Operational conditions : Ambient temperature : 0 ℃ ~40 ℃ ,

relative humidity ≤95% , water temperature range is 2 ℃ ~110 ℃ .

Keep ambient temperature lower than the water to avoid condensate in the stator .

Transmission fluid : The liquid which is clean , lean , non-corrosive ,

non-flammable / explosive and without any solid particles

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved