APPLICATIONS

MVP vibration pump is for clean-water submersible pump ,which is videly used for the irrigation,mine water drainage, as well as for flood control compaign in energy-conservation; This series pump well known for its steady performance and durability use, and it is also used for the river, lake,well and so on.

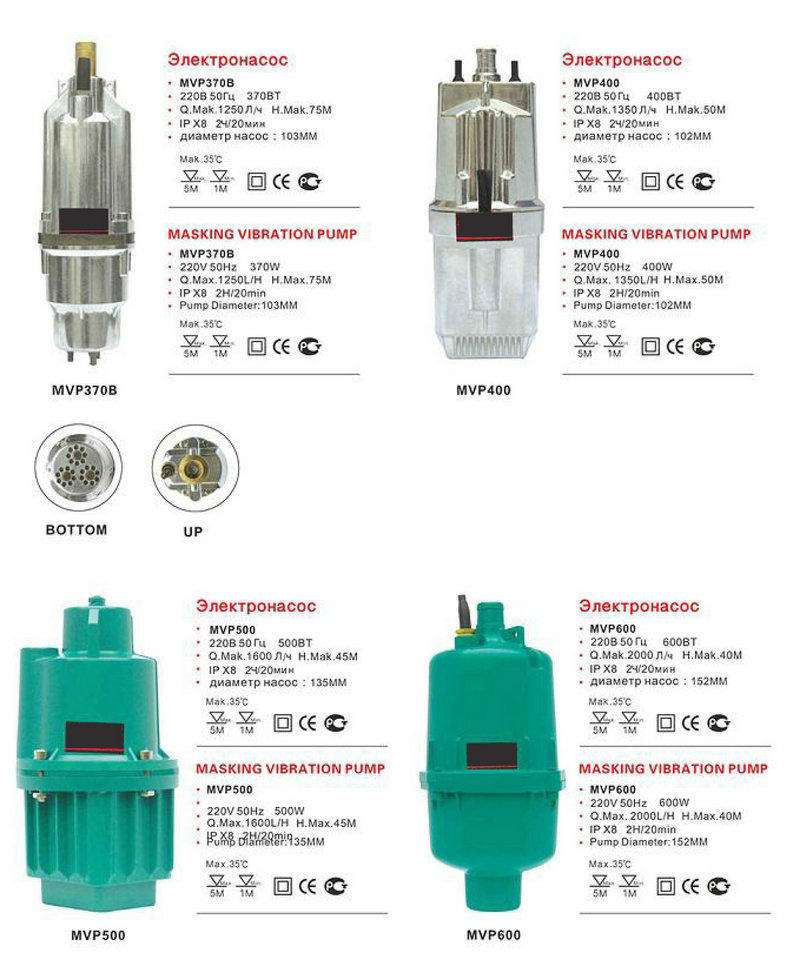

SPECIFICATION

1. Suitable Fluids : Clean Water;

2. Fluid Temperature Range : 0~40 degrees;

3. Max Working Pressure: 8Bar;

4. Power(single phase)220V± 5%/50HZ;

Model | Input Power | MAX. Flow | MAX. Head | Inlet/Outlet (IN) | GW Kg | Ctn. Dimension CBM. | Quantity | |

| Kw | Hp | L/Min | M | Set/Ctn | ||||

| MVP370B | 0.37 | 0.5 | 20 | 75 | 1/2 | 4.2 | 0.03 | 6 |

| MVP400 | 0.4 | 0.53 | 22 | 50 | 1/2 | 4.3 | 0.03 | 6 |

| MVP500 | 0.5 | 0.66 | 26 | 45 | 1/2 | 4.5 | 0.03 | 6 |

| MVP600 | 0.6 | 0.8 | 33 | 40 | 1/2 | 4.6 | 0.03 | 6 |

1. Dgree of protection:IP68;

2. Insulation class: B;

3. Pump Body :Aluminium;

4. Motor body: Aluminium;

5. Impeller: Rubber;

6. Shaft: 45#steel;

FREE ACCESSORIES

Rope, Impeller, Clap

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved