PUMP INSTALLATION AND APPLICATIONS

It can be used to transfer clean water or other liquids similar to

water in physical and chemical properties.It is suitable for

industrial use and urban water supply,pressure boosting for

high buildings and fire fighting,garden irrigation,long-distance

water transfer,heating ventilation and air controlling,circulation

and pressure boosting for cold and hot water,and supporting

equipment etc.

Model | Power | Q.MAX L/min | H.MAX m | S.Head m | Inlet/Outlet | G.W. Kg | Packaging Dimension mm | |

KW | HP | |||||||

1DK-14 | 0.37 | 0.5 | 75 | 14 | 8 | 1"X1" | 8 | 220X155X190 |

1DK-20 | 0.55 | 0.75 | 90 | 20 | 8 | 1"X1" | 11.5 | 315X210X220 |

1.5DK-20 | 0.75 | 1 | 220 | 16 | 8 | 1 1/2"X1 1/2" | 13 | 305X175X210 |

2DK-16 | 1.1 | 1.5 | 400 | 16 | 8 | 2"X2" | 16.5 | 355X220X265 |

2DK-20 | 1.5 | 2 | 450 | 20 | 8 | 2"X2" | 17.8 | 370X215X240 |

CM20 | 0.75 | 1 | 260 | 20 | 8 | 1 1/2"X1 1/2" | 14 | 310X175X225 |

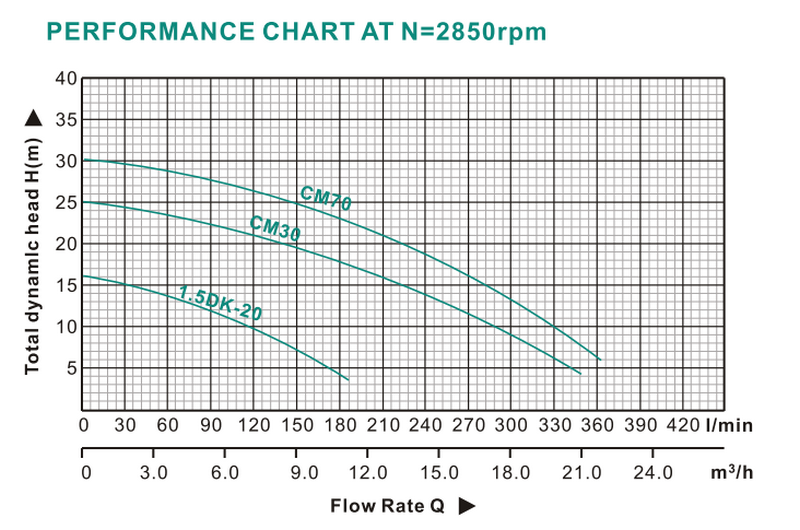

CM30 | 1.1 | 1.5 | 390 | 25 | 8 | 1 1/2"X1 1/2" | 15 | 390X240X295 |

CM70 | 1.5 | 2 | 400 | 30 | 8 | 2"X2" | 24.5 | 445X240X295 |

BG30N | 1.5 | 2 | 400 | 35 | 8 | 2"X2" | 25 | 465X255X310 |

BG50N | 2.2 | 3 | 460 | 40 | 8 | 2"X2" | 26 | 485X260X320 |

| 220-240V/50HZ,110V/60HZ, models are available on request | ||||||||

. Cast iron pump body and support

. Stainless steel/Brass impeller

. Max. Liquid temperature:+40℃

. Max Suction:+8m

. Motor with copper winding

. Shaft:Stainless steel welded shaft/45# steel be electroplated

. Insulation class:B or F

. Protection class:IP*4

. Max.Ambient temperature:40℃

. Cooling:External ventilation

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved