Product description

· [Easy use] Drinking Water Pump is easy to install and use, just press the pump. Water Hand Pump manual without power supply, innovative vacuum action, easy to pump. Uses vacuum action to dispense as quickly or a slowly as you like.

· [Easy clean] This Drinking Water Pump is lightweight, compact and easy to carry. Water Hand Pump is easy to remove and easy to clean. Press Manual Pump is very suitable for camping, sports, home, school, office, etc.

· [No BPA] Drinking Water Pump is made of 100 percent drinking water quality plastic. Water Hand Pump is made of high quality PP and PE. Press Manual Pump has an extremely long service life.

· [Versatility] Drinking Water Pump has a flexible adapter that can mount almost any 5-6 gallon water bottle. This Water Hand Pump is designed for pure water, mineral water and other barrel water users.

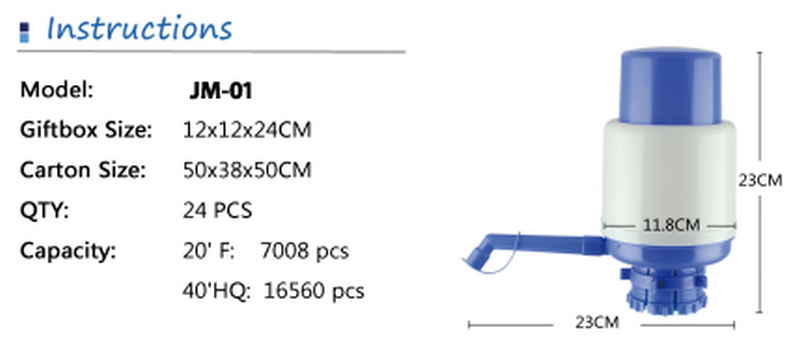

| Model | Giftbox Size(CM) | Carton Size(CM) | QTY |

| JM-01 | 12*12*24 | 50*38*50 | 24 |

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved